Certifications

Environmental

Label Makers Pty Ltd takes it’s environmental responsibilities very seriously and strives to reduce its environmental impact in every possible way.

Environmental Policy for Label Makers Pty Ltd

Environmental Policy for Label Makers Pty Ltd

Introduction

Label Makers Pty Ltd is a privately owned printing company, operating from a purpose built factory in Welshpool, Western Australia. Our main products are self-adhesive labels and other closely associated products. We recognise that our operations result in the generation of waste streams, and it is our aim to reduce the environmental impacts of our business and to operate in an environmentally responsible manner at all times. This policy describes how we will achieve our aim.

Responsibility

This environmental policy applies to all of our operations including management, office services, printing, delivery

and procurement. The Factory Manager is responsible for ensuring that the policy is implemented. However, all Label Makers staff, visitors and contractors have a responsibility to ensure that the aims and objectives of the policy are met.

Resources

The company directors will ensure that resources are available to enable Label Makers Pty Ltd to achieve its objectives and targets.

Objectives

During a process of continual improvement Label Makers will:

- Take steps to reduce the volume of waste sent to landfill and increase recycling activities;

- Actively monitor waste levels, and seek new manufacturing techniques and technologies to reduce waste production.

- Continue to invest in new technologies to reduce power consumption, such as low energy lighting installed March 2012, 36kw Solar Power installed October 2013, new fast changeover, energy efficient press installed 2015.

- Constantly review the environmental management system to reduce waste generation of all kinds.

- Work with customers and suppliers to ensure we are effectively managing and reducing our environmental impact.

Targets

To achieve our aims, we have set ourselves the following targets:

- Inform all LM customers and suppliers about our environmental policy and our commitment to reduce our environmental impact..

- Define good housekeeping for solvent and ink use.

- Ensure all employees continue to receive training in good housekeeping and waste minimisation, and incorporate this training into the induction programme for new employees.

- Continue to substitute general waste skips, for recycled waste bins. Recycled waste streams currently running at 24% of all waste generated. (Oct 18)

- Monitor waste levels and work towards an annual landfill waste reduction of 5% or more.

- Implement Lean Manufacturing techniques to reduce material wastage and unnecessary energy usage.

Monitoring and auditing

Waste levels are recorded and constantly monitored and measured against turnover levels. Progress against the policy objectives will be monitored through our monthly management meetings and the biannual review of the EMS.

Communication

This environmental policy is available on request. If you wish to obtain a copy or would like to discuss our

progress against our objectives, please telephone 1300 73 53 99.

Label Makers Gain HACCP Product Certification (FZP) for its Meat Inserts and Carcass Tags

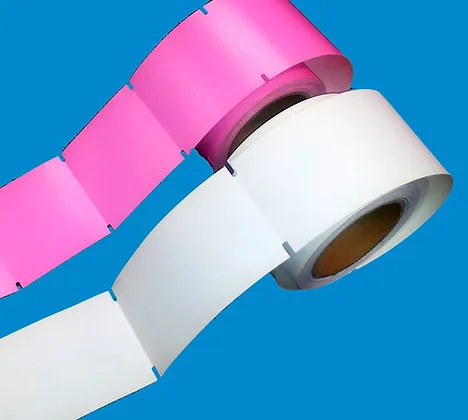

Label Makers are proud to announce their recent certification by HACCP Australia for Meat and Carcass Tag production. Our direct thermal, and thermal transfer tags have been tested and certified as suitable for direct food contact (Classification FZP – suitable for direct contact with food).

We have invested a great deal of time and resources into developing a product which was economically viable, in-line with our customer’s needs, and most importantly suitable for coming into direct contact with meat.

Our toughest challenge was producing a direct thermal tag that would also be suitable for contact with food. We worked with leading coatings suppliers and scientists to develop a product that is completely sealed to ensure there is no chance of any cross contamination, without affecting the performance of the product.

Our premises were audited by HACCP Australia, and a thorough review of our recently developed GMP system was conducted. Well the feedback was just awesome! Our facility has passed with flying colours, and we are very pleased to be offering fully certified products to the meat handling and packaging industry in Australia.

Our GMP system encompasses our commitment to producing high quality products consistently, and without presenting any risk of microbial, chemical or physical contamination during the process. We welcome our food and meat customers to visit our facility to sample the cleanliness and hygiene practices we have in place. Feel free to bring your dinner with you and eat it off the floors..!

Check out our HACCP Certified tags here